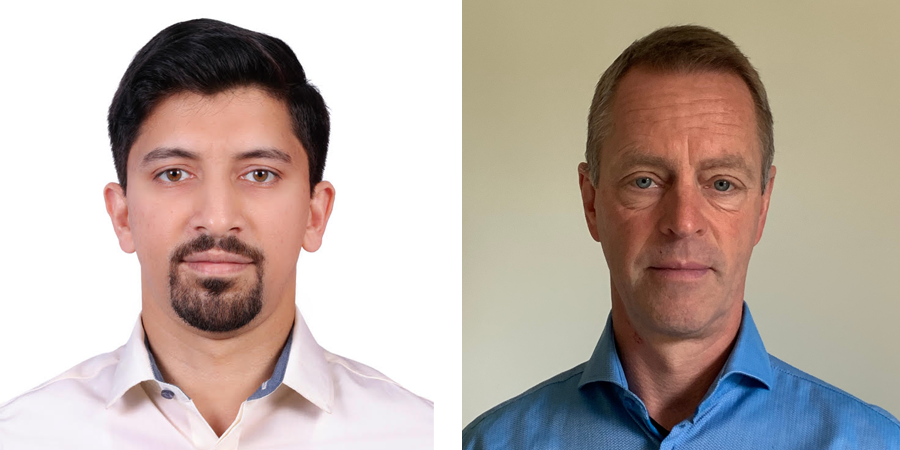

AVS Welcomes Shadh Ahamed Mullantakam as Outside Sales Manager in the Middle East and Appoints Cor Pauws as Managing Director

Advanced Valve Solutions (AVS) is thrilled to announce the appointment of Shadh Ahamed Mullantakam as the Outside Sales Manager for our Dubai office, marking a significant addition to our Middle East team. Shadh brings a wealth of experience and expertise to his new role, having previously worked with prestigious companies such as Fichtner, Mott MacDonald, Siemens, and Robtstone.

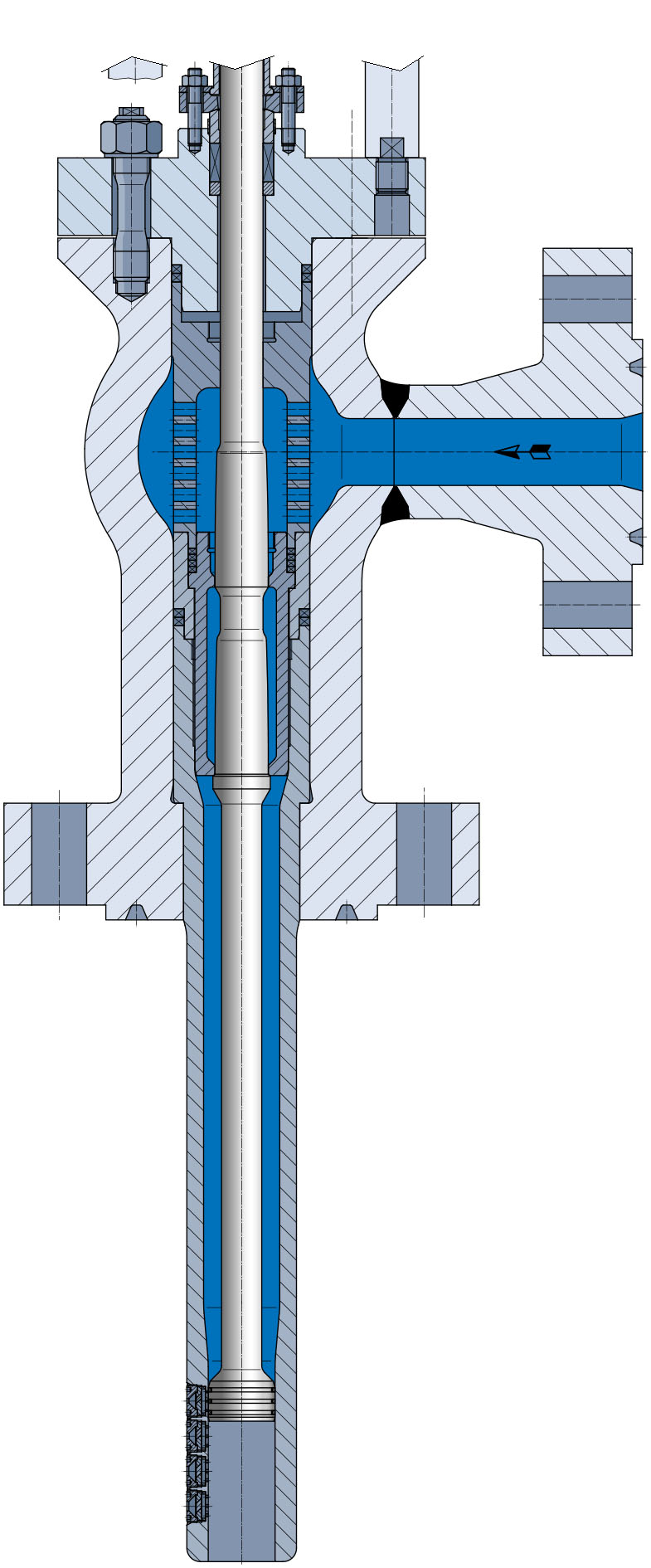

In his capacity as Outside Sales Manager, Shadh will oversee sales operations across key regions including the United Arab Emirates, Kingdom of Saudi Arabia, Oman, Qatar, and Bahrain. His background as a QA/QC Engineer and Mechanical Inspector will be invaluable in driving AVS's commitment to delivering tailored and innovative valve solutions that address the unique challenges faced by our customers. At AVS, we are dedicated to providing engineered valve solutions that solve complex issues, and Shadh's analytical approach and engineering curiosity align perfectly with our mission.

Please join us in extending a warm welcome to Shadh as he embarks on this exciting journey with AVS. We are confident that his contributions will further strengthen our capabilities and enhance the level of service we provide to our valued clients.

In addition to this exciting news, AVS underwent transformative changes in its leadership structure over the past years. On December 1st, 2022, AVS was acquired by Addtech AB from Sweden, marking a strategic move towards broader horizons and enhanced capabilities. This acquisition paved the way for further growth and expansion opportunities for AVS within the industry.

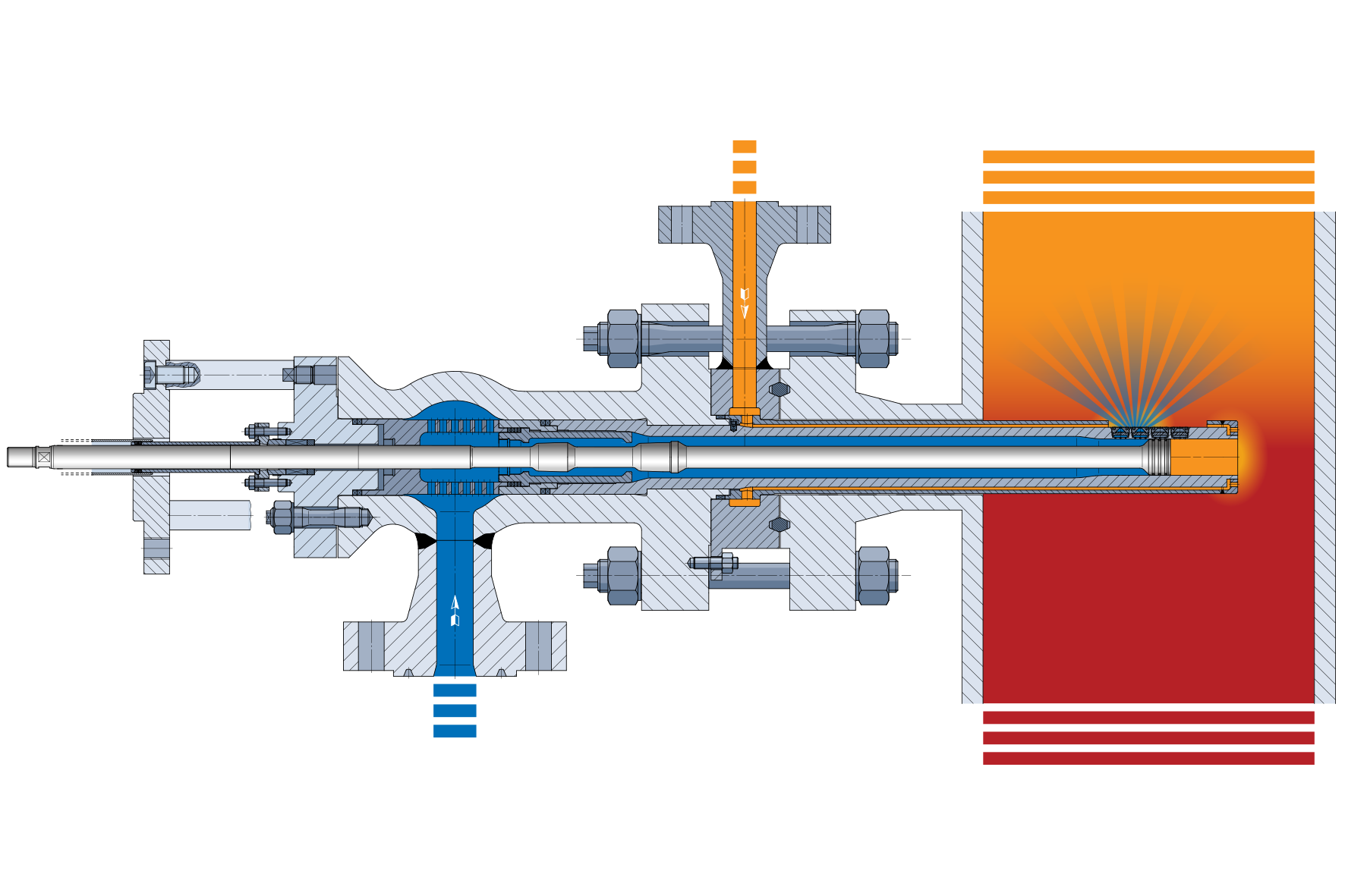

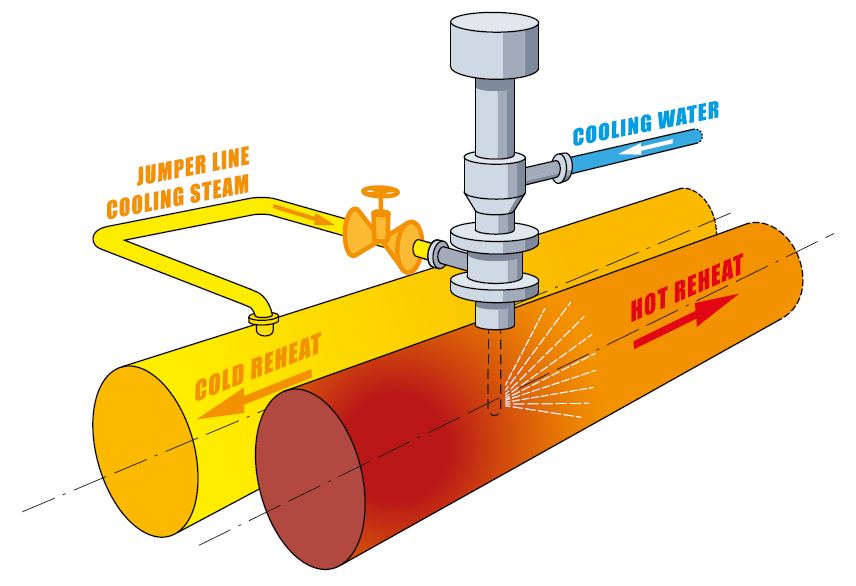

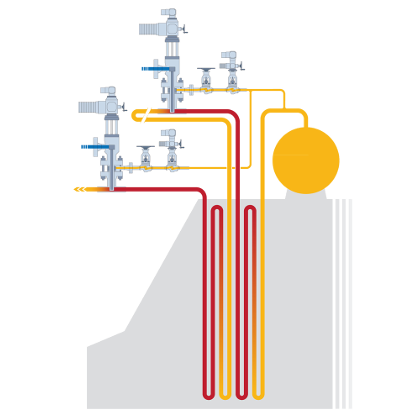

Exactly one year later, on December 1st, 2023, AVS witnessed another pivotal moment in its history as founder and owner, Karel van Wijk, stepped down from his role. Taking the reins as the new Managing Director is Cor Pauws, whose journey with AVS began in 2001, following a distinguished career that commenced in 1995 as a project engineer for Standard Fasel Lentjes in Utrecht. It was during this formative period that Cor laid the groundwork for what would become his the cornerstone of AVS's operations - an intricate understanding of the water/steam cycle within power plants and its translation into effective control valve solutions.

Over the years, Cor has held various positions within AVS, leveraging his expertise in HRSG and control valves to contribute significantly to the company's growth and success. His tenure as Manager Inside Sales since 2006 saw him leading a team of skilled professionals through the changing landscape of the energy market, navigating new challenges as AVS expanded its presence into international markets such as the UK, USA, and Dubai.

With Cor Pauws at the helm, supported by a dedicated and knowledgeable team, AVS is poised for a new phase of innovation and expansion. As we continue to adapt to evolving market dynamics and meet the diverse needs of our customers, we are confident in our ability to build upon our legacy of excellence and drive towards even greater achievements.

Please stay connected with us for the latest updates and insights from AVS.